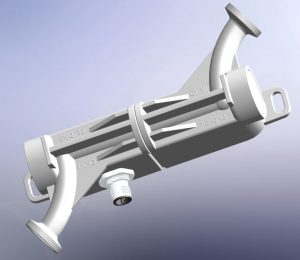

Single Use flowmeter at CPHI Frankfurt

CPHI Frankfurt will be an interesting event for users and OEM companies in pharma.

From 1-3 November, the CPHI Frankfurt will take place in Frankfurter Messe.

Flowmeister is excited to visit this exhibition for the first time.

2022 will be theme “Walking around”

Yes, Flowmeister would love to be present with a booth on CPHI Frankfurt.

On the other hand, with ACHEMA 2022 freshly in mind, we learned that your own booth limits the time to walk around and see other solutions, customers and partners.

For that reason, the Flowmeister-theme for CPHI Frankfurt 2022 will be ‘walking around’ only.

Note:

With the current perspectives in the Single Use market, we are optimistic about displaying our solutions in the next live event of CPHI.

See you at CPHI Frankfurt

Are you planning to visit CPHI Frankfurt as well, or should we definitely vist your booth?

Let’s plan a meeting!

Ask for more if you want to be updated on the #multiparameter aspects of our Single Use flowmeter.

A short mail to Flowmeister will do. (Please mention ‘CPHI Frankfurt flowmeter’ as a reference)

For your convenience: the CPHI registration link

Are you triggered by #Multiparameter #Flowmeter?

Can’t wait to read a little more ?

Check it here: Portfolio Flowmeister

Tip: Search for ‘CPHI Frankfurt flowmeter’ to find all available links and solutions related to this topic.